Fluid Bed Dryer :

Fluidized bed dryer is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules. The equipment works on a principle of fluidization of the feed materials. In fluidization process, hot air is introduced at high pressure through a perforated bed of moist solid particulate. The wet solids are lifted from the bottom and suspended in a stream of air (fluidized state). Heat transfer is accomplished by direct contact between the wet solid and hot gases. The vaporized liquid is carried away by the drying gases.

Tray Dryer :

Tray dryer A dryer utilized for drying of the wet products like crude drugs, chemicals, powders or the granules, etc. is known as tray dryer. A laboratory oven is the elementary form of it which contains a cabinet with a heater at the bottom. The values of these ovens are very less because of its uncontrollable heat transfer or humidity meter. When we fit a fan in the oven, the circulation of the forced hot air gets started. This process is beneficial for reducing the local flour concentrations and also for increasing the heat transfer. The directed circulation form is the best type of a tray dryer. In these Dryers, the air is heated and then focused on the object in a controlled flow.

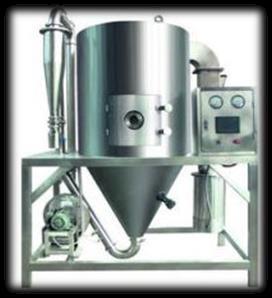

Spray Dryer :

SPRAY DRYER Mixer unit is a kind of centrifugal atomizer, which has centrifugal and pressure type. It can atomized solution, suspension liquid, emulsion and slurry into small drops of liquid (surface area increased), through the hot air to dry rapidly (within a few seconds to tens of seconds), thus directly get powder products. Raw material is throws out and atomized by centrifugal force role in rotary table (90-160 - m/s peripheral speed) from the plate edge, the whole system adopts hot air circulation drying

DOUBLE CONE VACUUM DRYER :

The DOUBLE CONE VACUUM DRYER also utilizes the vacuum drying technology with greater drying efficiency. Wet product goes through an indirect heating process and agitation with tumbling action, all while inside a vacuum to achieve rapid drying. In this process, recovery of solvent is also possible through condensation processes.

With constant innovation, the RVCD manufacturer has been able to deliver highly precise models that achieve thorough drying of product, uniformity of products, reduced drying time and an easy to clean and maintain machine. The roto cone vacuum dryer is mainly used in chemicals processing and pharmaceutical industries where air contamination can easily occur with other types of dryers.

ROTARRY VACCUM PADDLE DRYER :

ROTARRY VACCUM PADDLE DRYER or Paddle Dryer is used to obtain dry Powder from wet cake or solutions. The efficiency is very high and the operating costs are low compared to other types of dryers. It is a closed system in which hot water ,steam, or hot fluid is used as a heating medium in the jacket, in the hollow paddle and in the hallow shaft. Dust collector, condenser, receiver and vacuum pump are part of the system. The continuous agitation by means of heated rotating paddles and minimum clearance between scrapers and heated walls provide a good heat transfer to the wet feed.This results in the solvent/moisture evaporating off and renders the wet material dry, to the required degree. The vapors formed are removed by means of vacuum. Absence of large air flows virtually eliminates dust problems and also the energy consumption remains low.

Click Here To Open PPT File :

AGITATED NUTSCHE FILTER DRYER (ANFD): :

This is a combination of Filter and Dryer unit in single equipment to achieve economy in process and energy there by improving profitability. This equipment can be used in manufacturing process of various Pharmaceutical and Food Products, Chemicals, Agro Chemicals, Pesticides, Insecticides, Dyes and Intermediates. It is also available for Sterile applications.

Click Here To Open PPT File :