Industrial Mixer & Conveyors :

Mixing processes and mixer design depends upon the nature of the materials to be mixed. We have developed a wide range of mixing technologies to meet customer requirements in he needs of powder,paste,slurry and liquid application.

RIBBON BLENDER :

Ribbon Blender (also named ribbon mixer) is a basic industrial mixing machine. They consist, basically, of a trough-shaped shell (usually 2 to 3 times longer than it is wide) with a semicircular bottom, fitted with a horizontal longitudinal shaft on which are mounted arms supporting a combination of ribbon blades, paddles or helical screws set at a fairly close clearance to the semicircular mixer body so that no layer of material remains on the bottom of the ribbon mixer. The most effective design of ribbon layout is the double spiral in which the outer ribbon moves the product in one direction and the inner ribbon moves it in the opposite direction.

SINGLE / TWIN SHAFTS PADDLE MIXER :

Single / Twin Shafts Paddle Mixer consists of shape vessel, drive unit and double paddle shafts. The double shafts run in counter-rotation to make paddles turn over the materials in axial and radial direction of mixing action in fluidized zone. All the materials will be lifted in non-gravity status and also fall down to form a cross mixing. We can get perfect homogeneous mixing in very short time and almost all the materials can be emptied through full bottom discharge valve. Liquid Additions can also be sprayed at top of cover and mix with powder in short time. For some heat sensitive and fragile material, twin shafts paddle mixer can fulfill perfect mixing result.

Nauta Mixer :

Nauta Mixer is mixing equipment with high uniformity, low energy cost, low residue and low crush. There are two asymmetric spiral shafts, with their self-rotation and revolution, material are lifted repeatedly to finally realize the purpose of well-mixed. It is one of the earliest developed products and till now, it is widely used to mix powder-powder and powder-liquid, especially for fine powder, fiber & slice material.

Double Cone Blender :

Double Cone Blenders are used for mixing,lubricating and blending in Pharmaceutical, Chemical, and other Allied industries The Double shape blenders have long two corner of product container for more rubbing and tumbler effect to the material for fast and homogenizing mixing. It can perform homogenously dry mixing of free flowing powders, granules requiring low shearing force, Mixing and Blending of particles with rapid intermixing of particles irrespective of varying specific gravities.

Octagonal Blender :

Octagonal Blenders are used for mixing, lubricating and blending in Pharmaceutical, Nutraceutical, Food, Chemical, cosmetics, ceramics, pesticide, plastics and other Allied industries. The octagonal shape blenders have six corner of product container for more tumbler effect to the material for fast and homogenizing mixing. It can perform homogenously dry mixing of free flowing powders, granules requiring low shearing force, Mixing and Blending of particles with rapid intermixing of particles irrespective of varying specific gravities.

Mass Mixer :

Mass Mixer ideally used for mixing both wet & dry materials to provide uniform mixing. Designed with utmost precision & perfection our offered mass mixers are used for mixing & blending purposes..The mass mixer is suitable for mixing of wet mass, dry powder, dry powder with wet mass, etc,

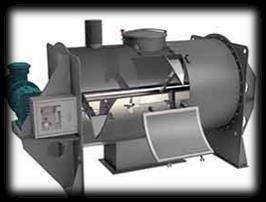

Plough Shear Mixer :

Plough Shear Mixer i (consists of a cylindrical drum containing plough shaped mixing elements that are mounted on a horizontal shaft. It creates a mechanical fluidized bed mixing action. The mixing tools project and hurl material away from the wall into free space in a crisscross direction, and inversely back again. The plow separates and lifts the product into three-dimensional motion, while the number and arrangement of the tools insure agitation back and forth along the length of the vessel.

V Blender :

Blender equipment is very useful in the pharmaceutical and food manufacturing industries. It is also referred to as the twin shell blender and is widely used in industry. This is because it offers a short blending time and highly efficient in operation. The machine is made up to 2 hollow cylindrical containers joined together at an angle of 75 to 90 0. As the V blender tumbles the material is continuously separated and recombined, and thorough mixing occurs as it falls randomly in the vessel.

Screw Conveyor :

Industrial Screw Conveyor uses a mechanism that makes use of a helical screw blade to move liquid or granular materials. Having a robust construction and huge load carrying capacity, these conveyors are manufactured using advanced and latest technology machines so as to offer precise dimensions and high efficiency.

Belt Conveyor :

A belt conveyor is simply an endless strap of flexible material stretched between two drums and supported at intervals on idler rollers. When the drum rotated by the driving motor, the belt will move with roller due to frictional resistance, there by the material placed on the belt will be transported from one place to other. Majority of belt conveyors are equipped with flat belts. Toughing the belt or fitting sidewalls will increase the carrying capacity. Fitting the transverse slats or texturing the surface of the belt will help to operate the belt conveyor for steep inclined application. The end of the conveyor where transported material is loaded is termed as ‘tail end’ or ‘feed end’ and the other end, from which the load is discharged, is called as ‘head end’.